Vacuum Filter ( Vacuum Disk - Belt - Tambor Filter )

It starts with the taking the product (prefiltered with the thickener) in to the tank. The product taken into the boat is adherent to the surface of the sector with the effect of the vacuum power provided by the vacuum pump, get rid of the liquid in it and directed to the discharge chute. Filtration process is carried out with this continuous cycle.

The sector group consists of 12 different sectors.5 of these sectors wrap the product in the boat, 6 of these sectors filter the product which is wrapped around and in the remaining 1 sector throws the product by blowing on itself.

Major Parts

Main Construction; Special design that can resist the forces to be applied and wear over time.

Vacuum Filter Sectors; Specially designed sectors to increase the ability of filtration.

Vacuum Filter Cloths; It is a cloth specified by product with permeability and durability.

Vacuum Filter Drive Group ; A drive group that drives the product and main shaft which the sector group is connected in a continuous cycle.

Vacuum Filter Dip Mixer; The bottom mixer prevents the product from falling into the bottom of the vessel and allows the product to be filtered as a homogeneous mixture.

Electrical Control Board; Thanks to software designed by our company for equipment provides maximum performance, minimum time principle, user convenience, reporting plugins can be followed and convenience to the end user.

Vacuum Filter Vacuum Head; Thanks to special design vacuum head makes respectively product wrap to sectors, filtration and lastly discharged the product by blowing.

Vacuum Pump; It is designed for the variable flow and power varying according to the filter capacity, it meets the vacuum needs of the system.

Vacuum Filter Blower; It is designed for different flow rates and forces to be used to direct the filtered product to the discharge chamber.

Vacuum Filter Filter Separator; It provides removal of the filtrate from the system without the need for a barometric foot or extraction pump which must be used to remove the filtrate from vacuum power.

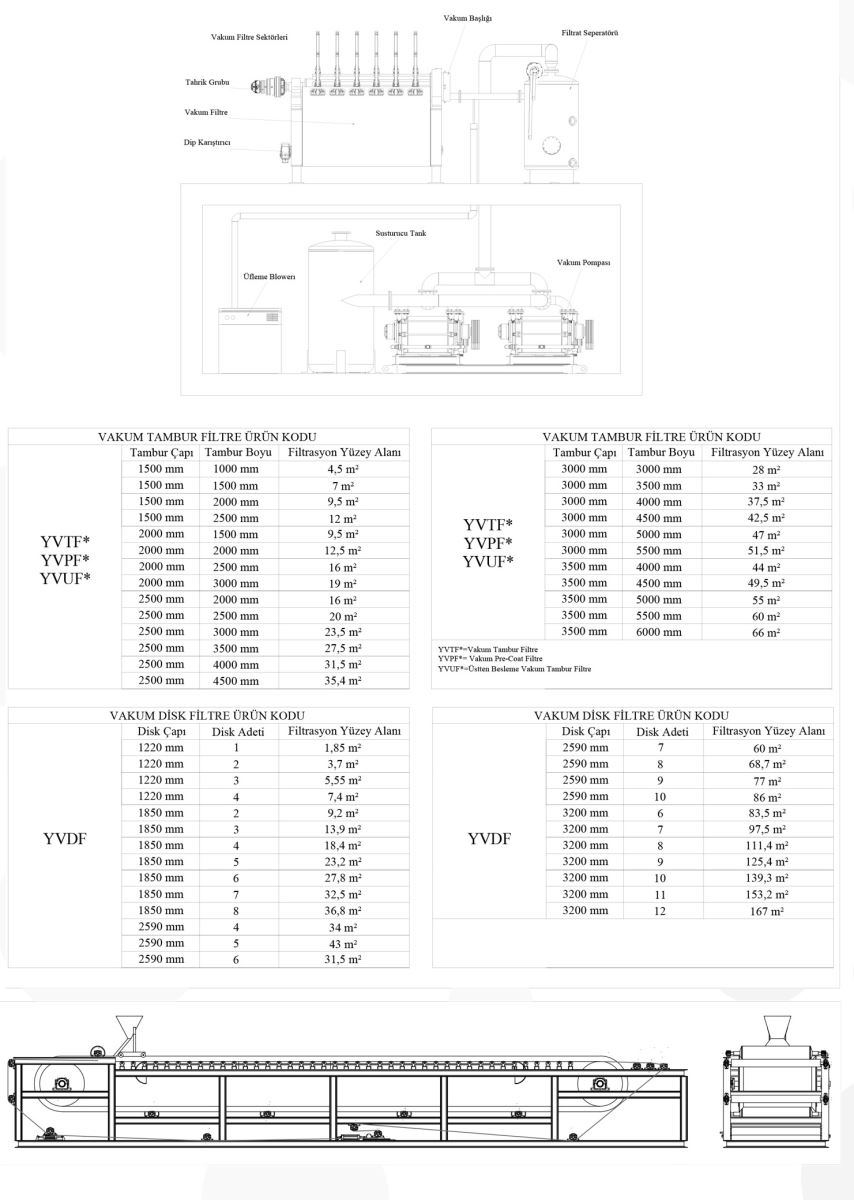

Vacuum Drum Filter; In general, the system used in the mining, chemical and food sectors provide high efficiency, low product humidity with 4.5 m²-66 m² vacuum surface area.

Vacuum Disc Filter; In general, the system used in the mining, chemical and food sectors provide high efficiency, low product humidity with 1,85 m²-167 m² vacuum surface area. The only difference of the vacuum disc filter, which is the same working principle as the vacuum drum filter, is the high filtration area.

Vacuum Pre-Coat Filter; In general, the system used in the mining, chemical and food sectors provide high efficiency, low product humidity with 4.5 m²-66 m² vacuum surface area. It is used in filtration of products with low density, having the same physical structure as vacuum drum filter. This type of filter is used as an extra filtration aid and the filtration surface is narrowed to prevent escaping thin particles in products as the filtrate.

Top Feeding Vacuum Drum Filter; In general, the system used in the mining, chemical and food sectors provide high efficiency, low product humidity with 4.5 m²-66 m² vacuum surface area. It has the same physical structure with the vacuum drum filter. It is used in the filtration of the products that can quickly collapse into the bottom of the boat if it is found as coarse in the liquid. Only the feed type is changed.

Vacuum Belt Filter; By the structure, the product coming out of the press filter is discharged to the bottom. It is a kind of filter which is used for the filtration of the products which have easy grain filtration. It is based on the removal of the liquid in the product by vacuuming the product that runs along a flat band through the filter. The size and capacity of the process can be manufactured by our company.