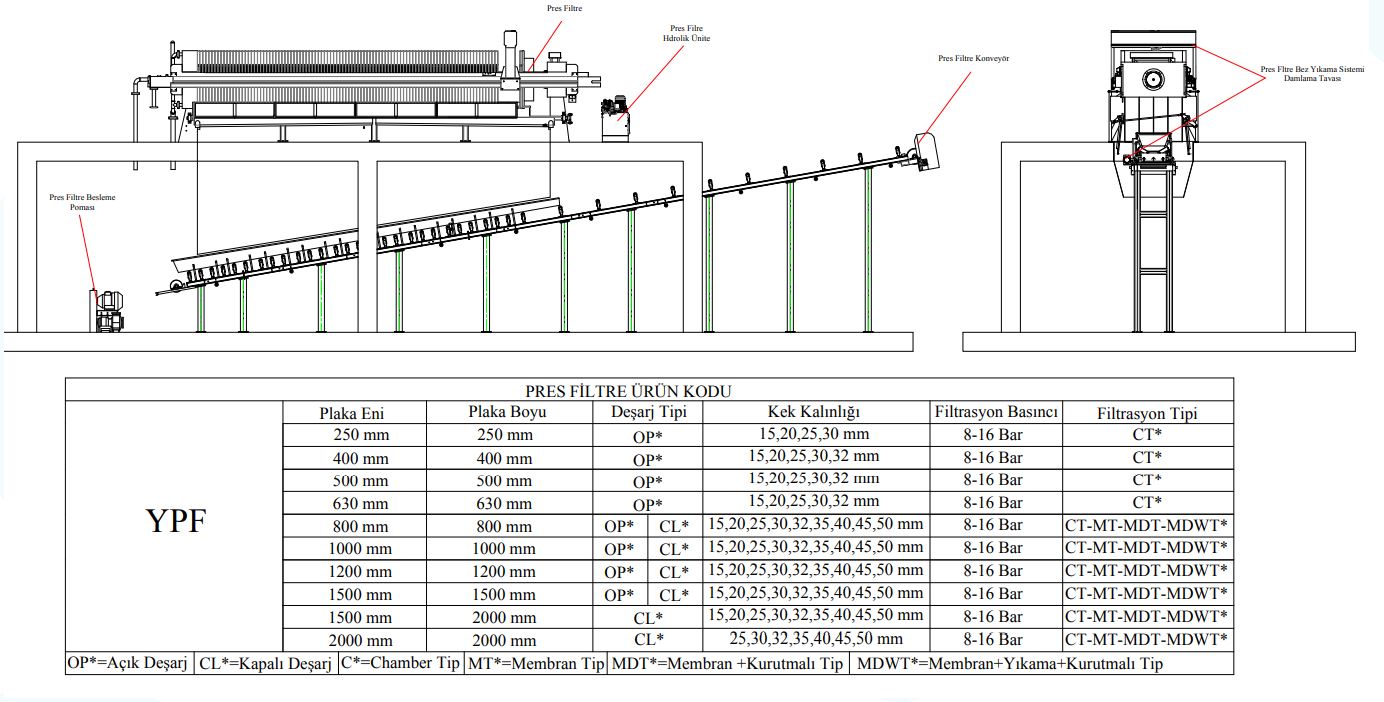

Press Filter

The oldest known and most widely used (mine, food, chemistry, biological and physical treatment plants etc.) filtration equipment. It is used frequently in filtration solutions with the technology added over time. The working principle of the system is to fill the volumetric cavity formed between the plates with the hydraulic power by taking advantage of the power of the pump thus the product is sent away from the liquid.

Pres Filter Plates

Specially designed plates to increase the ability of filtration.

Main Parts

Main Construction; Special design that can withstand the forces to be applied and wear over time.

Press Filter Plates; Specially designed plates to increase the ability of filtration.

Press Filter Cloths; Cloths are determined separately for each product. They have durability and permeability.

Press Filter Hydraulic Unit; It is designed to produce hydraulic power to be used.

Press Filter Feed Pump; It is used to fill the product into the volumes created between the plates.

Press Filter Electric Control Panel; The software is designed by our company for the equipment. This software provides maximum performance, minimum time principle, user convenience and traceable with the additions to the last user.

Capacity and Calculation Criteria; Some analyzes are made in our laboratory with the product samples sent to our company. According to the results obtained, the dimensions and equipment design required by the process are determined and production begins.

Press Filter Types

Chamber Type Press Filter; It is the most commonly used type of press filter. The volumetric cavity formed between the plates filled by using the power of the pump with the hydraulic power and the liquid is removed from the product.

Membrane Type Press Filter; It is the type of press filter used when it is desired to obtain the lower humidity rate of the product compare with chamber type after filtration process. After the filtration process using the power of the filter feed pump, thanks to membrane diaphragms in the filter plates, the product is compressed more in the plate cavity and more liquid is removed from the environment. In this way, the product humidity is lower than the chamber type press filter.

Membrane + Product Drying Type Press Filter; It is the type of press filter used when it is desired that the humidity of the product to be obtained is lower. Air is supplied to the product whose humidity is reduced with the membrane plate. To obtain a product with lower humidity content, humidity molecules removed from the product with this way.

Membrane + Product Washing + Product Drying Type Press Filter; In the product to be filtered, there may also be different by-products which must be removed by washing. Membrane and product drying processes are carried out in order to reach the targeted humidity content after the by-products to be removed from the product during charging.

Accessories

Automatic Plate Opening Mechanism; Thanks to the mechanism located on the press filter, the plates are opened automatically and the cake is discharged. After all the plates on the press filter are empty, they come to the first position and ready for the next charge. This feature provides ease of use and prevents time loss.

Automatic Cloth Washing and Dripping Pan; It provides automatic washing of the cloths on the plates used during filtration. This feature increases the service life of the filter cloth on the plate, it also increases the filtration capability.

Static Cake Crusher and Router Chute; It facilitates the transfer of the product in the form of ingots formed after filtration and allows removal from the filter in smaller pieces.

Dynamic Cake Crusher and Router Chute; The product coming out of the filter should be separated into small pieces if the process is directed to a drying oven. This is the press filter accessory we designed to find solutions to such needs.

Product Transfer Conveyor; Due to its structure, the product coming out of the press filter is discharged just below the filter. It can be added to the system to transfer the product discharged underneath to another region with conveyor.